Formerly, acetate plastic has been mainly made from cellulose acetate and phthalate plasticizer Centered in the EU, the trend is for increasing regulation against the use of phthalate-related chemical substances Daicel has developed a new non-phthalate plasticizer and realized a phthalate-free acetate plastic

The transparency, impact and oil resistance properties of acetate plastic are maintained Dimensional stability is superior to standard acetate plastics

Acety EC

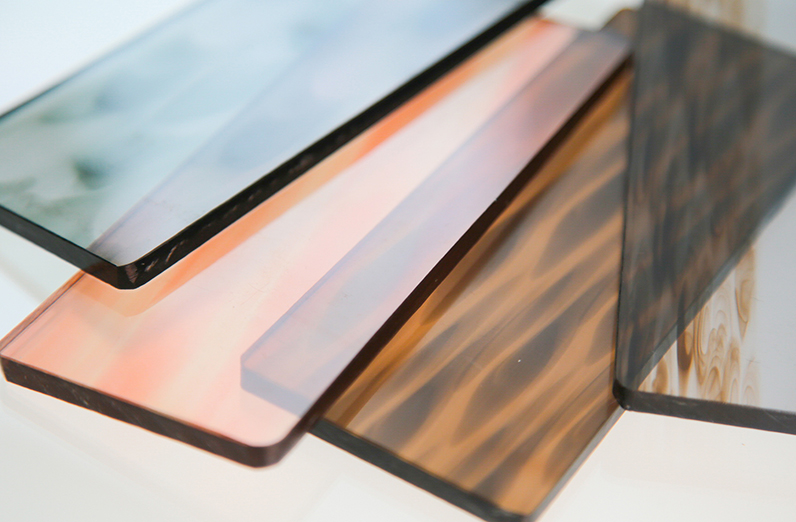

● All exist extrusion sheets including mono color & pattern can be produced by Acety EC.

● Acety EC sheets can be made to eyewear with the same process as normal acetate sheets.

● Wet block & Dry block sheets will be launched in the future.

Acety EC

● In comparison to standard injection molding frame materials, Acety has superior luster and gloss, as well as a pleasant texture

Using only a polishing process, a high gloss can be achieved without coating

● Dimensional stability is superior, and thinner frames can be realized compared to standard acetate plastics

● From raw materials to compounding, all manufacturing is located in Japan

| Properties | Test method | Unit | Condition | ECP E0001-20 | ECP E0001-26 |

|---|---|---|---|---|---|

| Density | ISO1183 | g/cm3 | 1.28 | 1.27 | |

| Melt Flow Rate | ISO1133 | g/10min | 220℃×10kg | 21 | 67 |

| Tensile Strength | ISO527 | MPa | 52 | 41 | |

| Flexural Strength | ISO178 | MPa | 67 | 45 | |

| Flexural Modulus | ISO178 | MPa | 2700 | 1900 | |

| Impact Strength, Charpy | ISO179/1eA | kJ/m2 | 23℃ | 8 | 17 |

| DTUL | ISO75 | ℃ | 0.45MPa | 94 | 66 |

| 1.8MPa | 70 | 52 |